Purpose & Results

Collecting end of life tyres for a cleaner environment

In the Netherlands RecyBEM collects all used tyres from the aftermarket, some eight million used tyres annually, and makes sure they are processed in an environmentally-friendly way. We recycle and re-use ninety percent of the tyres collected. The RecyBEM system yields raw materials and energy. Our system also leads to a reduction of CO₂ emission.

Collection of cartyres

For each new tyre producers (manufacturers and importers) bring into the Dutch market, they are required to collect an end of life tyre free of charge. RecyBEM’s market coverage is virtually one hundred percent.

Environmentally-friendly processing of cartyres

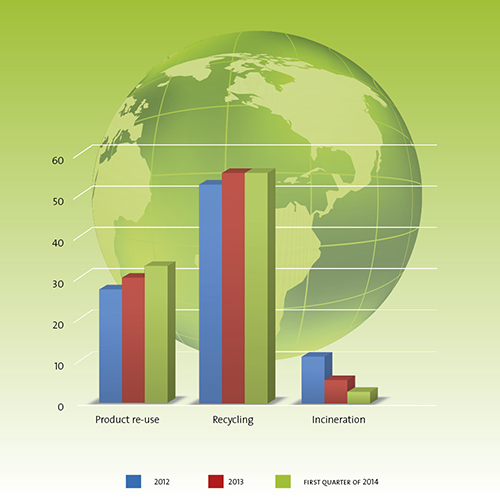

According to the Dutch legislation on end of life tyres, processing must focus on material re-use, product re-use, beneficial alternative use or incineration (with energy recovery), whereby at least twenty percent of the tyres collected must be processed for material re-use. In the Netherlands, we process far more tyres as material re-use. RecyBEM achieves no less than sixty to seventy percent. We hold our RecyBEM-certified collection companies responsible for ensuring that at least ninety percent of the tyres collected are destined for material and product re-use, and that at least fifty percent of the tyres collected must be destined for material re-use.

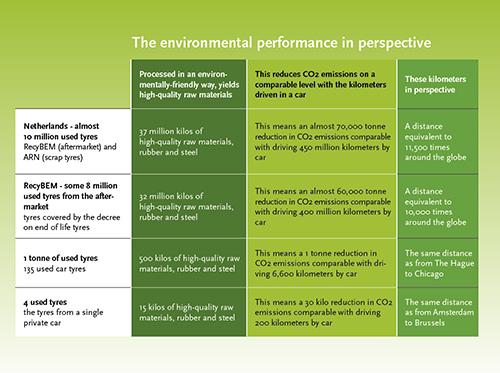

Reduced CO₂ emissions and raw materials savings

We process the tyres that are collected in the most advanced way possible, but we are constantly looking for potential improvements. For example in the area of our CO₂ footprint. We use Ecotest to determine the burden on the environment. This enables us to look at those areas where we can optimize our environmental performance. We investigate the coherence between ecology (CO₂ footprint), recycling (raw materials recovery) and economics (costs). The Ecotest results demonstrate that RecyBEM is ensuring a cleaner environment:

- RecyBEM encourages recycling as a processing method.

- RecyBEM achieves a high percentage of material re-use by recycling sixty percent of the tyres collected. This is above the legally required twenty percent as defined in the Management of Car Tyres Resolution.

- RecyBEM achieves a high level of CO₂ emissions savings.

- RecyBEM ensures raw materials savings.